Related products

live a message

Stainless steel coil are divided into austenite, ferrite, martensite, dual-phase (ferrite-austenite) cold rolled coils and hot rolled coils. In order to ensure that the mechanical properties such as yield strength, tensile strength, elongation and hardness of various stainless steel coils meet the requirements, the stainless steel coils must undergo annealing, solution treatment, aging treatment and other heat treatments before delivery. The corrosion resistance of stainless steel coils mainly depends on its alloy composition (chromium, nickel, titanium, silicon, aluminum, etc.) and the internal structure of the stainless steel coils. The main role is chromium. Chromium has high chemical stability and can form a passivation film on the surface of steel to isolate the metal from the outside world, protect the steel plate from oxidation, and increase the corrosion resistance of the steel plate. After the passivation film is destroyed, the corrosion resistance decreases.

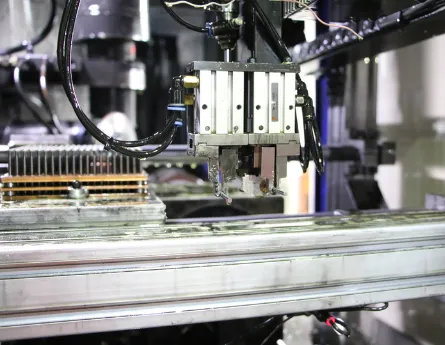

The process of dull polishing stainless steel sheet and plates involves using an abrasive belt on the surface to change the finish of the metal. Stainless steel sheets and stainless steel coils are normally supplied from the mill in one of two finishes – either 2B or 2R (bright annealed)*. This metal can be polished to achieve a desired finish and the type and direction of polish depends on the abrasive and process used. thyssenkrupp Materials (UK) supplies a wide range of polished stainless steel from stock as well as having in group capabilities to offer many more finishes.

Surface Finish | Definition | Application |

2B | Finished by heat treatment , picking or equipvalent cold rolling , followed by skin pass to obtain adequate luster surface. | With bright and smooth surface ,easy for further grinding to obtain brighter surface ,suitable for medical instruments ,milk containers ,tableware and so on. |

BA | Bright heat treatment after cold rolling. | Structual members .etc.kitchen utensil ,cutlery ,eleltric applicances ,medical instruments ,building decorations ,etc. |

NO.3/NO.4 | Polished with No.150-240 abrasives. | Milky food processing equipment , medicalinstruments ,building decorations. |

HL | Finshed by polishing with abrasives of suitable grain size to obtain continuous streaks. | Building decorations ,such as elevators ,escalators ,door etc. |

6K/8K | A mirror-like reflective surface ,which is obtained by polishing with successively finer abrasives and buffing extensively with all gritlines are removed. | Buliding entrances,bulkding column casting ,elevator's wall doors ,counters,sculptures etc. |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

Technology & Innovation

Team & Quality

Service & Support

| stainless steel 304 coil | stainless steel coil roll |

| stainless steel 304 coil prices | stainless steel coil rod |

| stainless steel 316l coils | stainless steel cold rolled coils |

| stainless steel 409 coils manufacturer | stainless steel flat rolled coil |

| stainless steel alien coils | stainless steel hot rolled coil |

| stainless steel coil factory | stainless steel mesh coil |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat