Related products

live a message

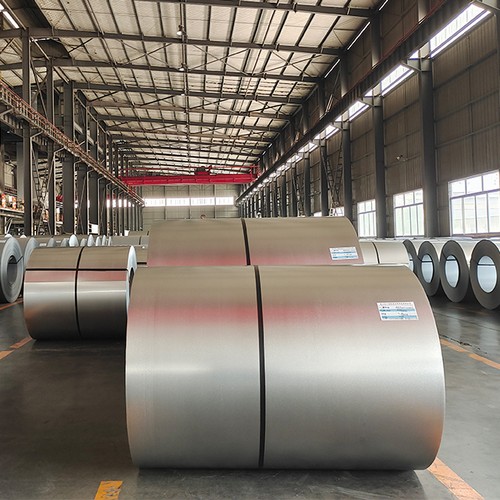

The term "aluminum coil" describes aluminum that has been flattened into sheets where their width is significantly higher than their thickness and then "coiled" into a roll. Stacks of individual aluminum sheets are difficult to store due to the potential of inconsistent sizes and individual sheets are difficult to retrieve and carry. Coils of aluminum sheets, on the other hand, are easy to store and transport.

Non-corrosive:

Even in industrial environments where other metals are frequently corroded, aluminum is extremely resistant to weathering and corrosion. Several acids won't cause it to corrode. Aluminum naturally generates a thin but effective oxide layer that inhibits further oxidation, giving it exceptional corrosion resistance. As a result, objects made from aluminum oxide are nearly impermeable to many corrosive substances.

Easily machined and cast:

Since it melts more readily than steel, aluminum coil is more pliable and simpler to pour into molds. Aluminum castings are also less stiff than steel, making them easier to work with while steel castings need a lot more effort. It is one of the most machinable metals available, making processing time cost-effective.

Lightweight yet durable:

Aluminum coil is lightweight and portable since it has a low density. This makes it the chosen metal for use in the construction of airplanes. It may be considered as being even more durable since it can be recycled.

Non-magnetic and non-sparking:

Aluminum is non-magnetic because of its crystalline structure. An oxide layer is quickly formed after any scratch making it non-sparking.

Good thermal and electrical conductor:

Free electrons in the structure of aluminum coils make it a good electrical conductor. Since there is a steady flow of these electrons, the aluminum coil is therefore a good conductor of heat.

Soft:

Aluminum coils are soft because of the available free electrons for bonding.

Non-toxic:

Exposure to aluminum is not harmful to the body.

Aluminium Alloy | Thickness(mm) | Width(mm) | Temper |

1000,2000,3000,5000,6000,7000,8000 series | 0.2-8.0/customized | 20-2300/customized | O,H12,H14,H16,H18,H22,H24,H26 |

Material process | CC AND DC | ||

Customerize size | Size can be produced as per clients requirement | ||

Surface | Mill finish ,Color coated(PVDF& PE),Stucco Embossed ,Bright Polish,Anodizing | ||

Mirror,Brush,Perforated,Tread plate ,Corrugated etc | |||

Quality Standard | ASTM B209,EN573-1 | ||

MOQ per size | 1 ton | ||

Payment Terms | TT OR LC at sight | ||

Delivery time | Within 25 days after receipt the lc or deposit | ||

Material Quality | Tension levelled ,flat ,Free of defects like oil stain,Roll Marks,Waves,Dents | ||

scratches etc ,A+++ quality, production process passed sgs and bv inspection | |||

Application | Construction ,Building,Decoration ,Curtain Wall ,Roofing,Mould,Lighting, | ||

curtain wall, ship building,Aircraft,Oil Tank ,Truck Body etc | |||

Packing | Standard export worthy wooden pallets/ as requirement | ||

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat