Related products

live a message

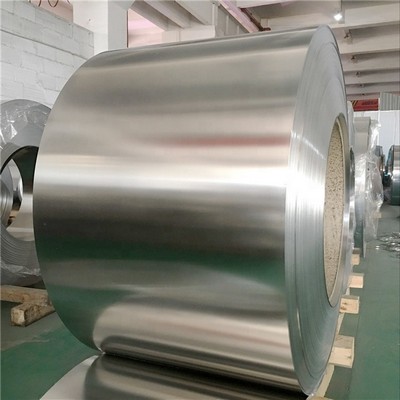

ss 301/304 Stainless Steel Coil 301 stainless steel is an austenitic stainless steel with 17 percent chromium and 7 percent nickel, ensuring good strength and ductility when cold worked. Besides, it also has excellent corrosion resistance properties.

301 stainless steel coil is a metastable austenitic stainless steel that has a complete austenitic structure under full solid solution conditions. Among stainless steels, 301 is the steel type that is most easily strengthened by cold deformation. Through cold deformation processing, the strength and hardness of the steel can be improved, and sufficient plasticity and toughness can be retained. In addition, this steel has good rust resistance under atmospheric conditions. 301 is mainly used in the cold working state for equipment parts that can cope with higher loads, reduce the weight of the equipment and make it rust-free. In addition, this steel is prone to work hardening when impacted by external forces and can absorb more impact energy, providing more reliable safety protection for equipment and personnel. However, 301 stainless steel coil has poor corrosion resistance in chemical media such as acid, alkali and salt, so it is not recommended for use in harsh corrosive environments.

Product Name | 301 Stainless Steel Coil |

Type | Steel Coil |

Thickness | 2.5mm-10.0mm |

Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

Width | 610mm-2000mm |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

Certificate | ISO, SGS, BV, etc. |

Production Technology | Hot Rolling, Cold Rolling |

Edge Processing | Edging, Trimming |

Chemical Composition

C | Si | Mn | Cr | Ni | S | P |

≤ 0.15 | ≤1.0 | ≤ 2.0 | 16.0~18.0 | 6.0~8.0 | ≤ 0.03 | ≤ 0.045 |

Mechanical Properties

Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

≥ 520 | ≥ 205 | ≥ 40 | ≤ 187HB ;≤ 90HRB;≤ 200HV |

Physical Performance

Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(μohm.in) |

7.88 | 193 | 16.9 | 16.2 | 27.4 |

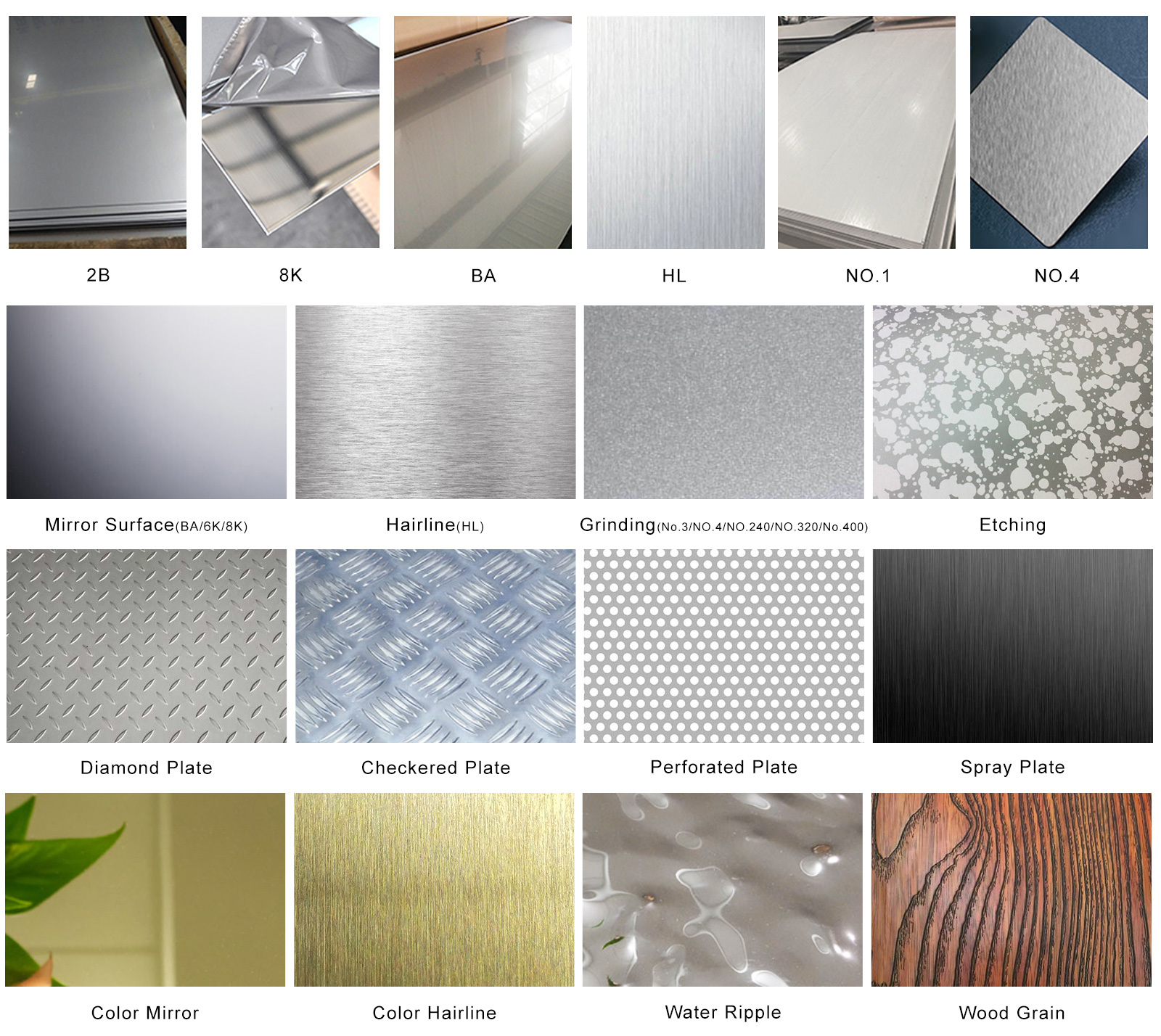

Surface Selection

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

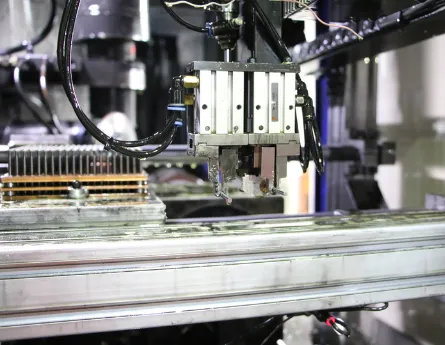

Technology & Innovation

Team & Quality

Service & Support

| stainless steel pre made coils | wholesale 316 stainless steel coil |

| stainless steel premade coils | wholesale hot rolled stainless steel coil |

| stainless steel pressure washer coil | wholesale stainless steel strip coil |

| stainless steel proof coil chain | using stainless steel coils |

| stainless steel rda coils | 0.28 and stainless steel coils |

| stainless steel ring shank coil nails | 0.2mm stainless steel coil/sheet/strip |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat