Related products

live a message

410 stainless steel is a commonly used martensitic stainless steel whose main components are iron, carbon, chromium and a small amount of other elements.

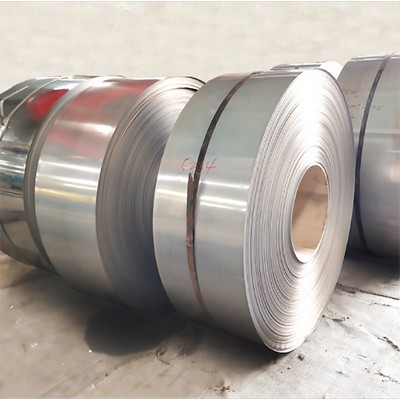

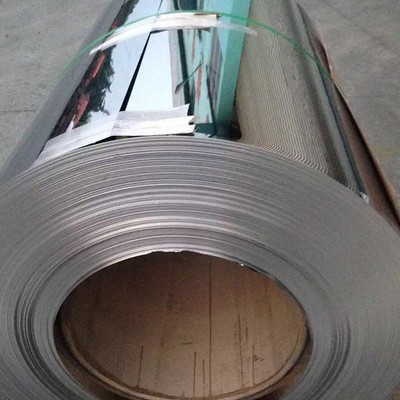

410 Stainless Steel – a corrosion and heat-resistant 12% chromium steel, stands as the most popular among the hardenable stainless steels. When heat-treated, it exhibits mechanical properties that mirror those of the engineering alloy steel AISI 4130, offering a perfect blend of strength and ductility. As a leading provider of 410 cold rolled coils, we excel in offering specialized slitting services and a vast array of sheet stocks, demonstrating our dedication to supplying superior-quality stainless steel solutions tailored to meet diverse industrial needs.

Grade 410 stainless steel belongs to the martensitic family of stainless steels, characterized by its 11.5% chromium content which offers respectable corrosion resistance qualities. The corrosion resistance can be optimized through hardening, tempering, and polishing processes. This grade is capable of being quenched and tempered, resulting in increased hardness.

Primarily chosen for its balance between mild corrosion resistance, heat resistance, and high strength, 410 stainless steel is suitable for various applications. Although it’s martensitic and requires final heat treatment during fabrication, it may exhibit lower corrosion resistance compared to austenitic stainless steel grades and can experience a reduction in strength at elevated temperatures as well as diminished ductility in sub-zero environments.

Corrosion Resistance: 410 stainless steel exhibits resistance to a variety of environments including hot gases, steam, food, mild acids, alkalis, fresh water, and dry air. Optimal corrosion and heat resistance are achieved through hardening, although it's noteworthy that 410 exhibits less corrosion resistance compared to austenitic and 17% chromium ferritic stainless steels. A smooth surface enhances its corrosion resistance capabilities.

Heat Resistance: This grade offers commendable scaling resistance up to 650°C, with a caveat that mechanical properties may degrade in the 400 to 580°C range.

Heat Treating 410 stainless steel:

Welding: Weldable by all standard methods; however, pre-heating at 150 to 260°C and post-weld annealing are advised to prevent cracking. Using grade 410 welding rods is recommended, with grade 309 filler rods as an alternative for more ductile joints.

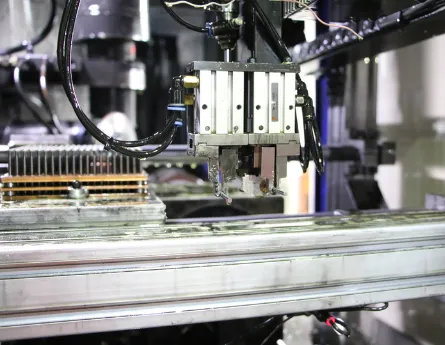

Machining: Machinability is optimal in annealed or highly tempered states. Hardened conditions above 30HRC diminish machinability, with grade 416 being a preferable option for easier machining.

Product Name | 410 Stainless Steel Coil |

Type | Steel Coil |

Thickness | 2.5mm-10.0mm |

Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

Width | 610mm-2000mm |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

Certificate | ISO, SGS, BV, etc. |

Production Technology | Hot Rolling, Cold Rolling |

Edge Processing | Edging, Trimming |

Chemical composition and mechanical properties of stainless steel coils | |||||||||

Grade | Chemical Composition (%) | Mechanical Performance | |||||||

C | Si | Mn | P | S | Ni | Cr | Mo | Hardness | |

201 | ≤0.15 | ≤1.00 | 5.5/7.5 | ≤0.060 | ≤0.03 | 3.5/5.5 | 16.0/18.0 | - | HB≤241,HRB≤100, HV≤240 |

304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 8.0/11.0 | 18.0/20.0 | - | HB≤187,HRB≤90,HV≤200 |

316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.0/14.0 | 16.0/18.0 | 2.0/3.0 | HB≤187,HRB≤90,HV≤200 |

316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.045 | ≤0.03 | 10.0/14.0 | 16.0/18.0 | 2.0/3.0 | HB≤187,HRB≤90,HV≤200 |

410 | ≤0.15 | ≤1.00 | ≤1.25 | ≤0.060 | ≤0.03 | ≤0.060 | 11.5/13.5 | - | HB≤183, HRB≤88 HV≤200 |

430 | ≤0.12 | ≤1.00 | ≤1.25 | ≤0.040 | ≤0.03 | - | 16.0/18.0 | - | HB≤183, HRB≤88 HV≤200 |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

Technology & Innovation

Team & Quality

Service & Support

| 430 stainless steel coil | hot rolled stainless steel coil |

| 410 stainless steel coil suppliers | polished stainless steel coil |

| 50 ft stainless steel coil | pre made stainless steel coils |

| 50 stainless steel coil | prebuilt stainless steel coils |

| buy stainless steel coil | premade stainless steel coils |

| china stainless steel coil | stainless steel 304 coil |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat