Related products

live a message

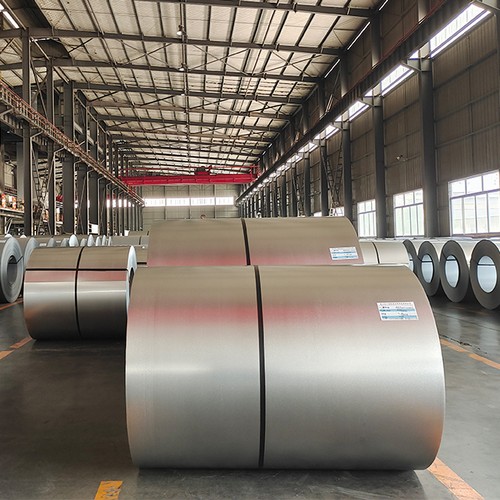

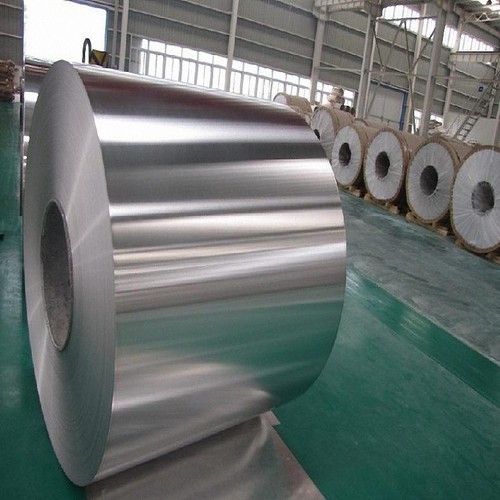

Aluminum coils are metal strips manufactured by casting and rolling mills. Aluminum coils are widely used in electronics, packaging, construction, machinery and other fields. According to the different metal elements contained in the aluminum coil, the aluminum coil can be roughly divided into 9 categories: 1000, 2000, 3000, 4000, 5000, 6000, 7000, 8000, 9000 series.

What is 3005 aluminum? 3005 aluminum coil belongs to 3 series aluminum alloy coil. 3005 aluminum alloy (Al-Mg) is approximately 20% higher strength than alloy 3003 with superior corrosion resistance. 3000 series aluminum coil is also called anti-rust aluminum. Manganese is added to 3005, contenting 1.0% -1.5%, so it has a better anti-rust function and is widely used. But the price is much higher than the 1000 series.

3005 aluminum coil is often applied for moist conditions such as air conditioner, refrigerator, the bottom of cars, etc. It is also commonly used for building materials or color-coated aluminum. It can be processed for some component parts which need good formability, high corrosion resistance, and good weldability, or some applications require these properties must higher than 1 series aluminum, such as kitchenware, processing and storage devices of food and chemical products, tank or vessel which transports liquid products and various pressure artifacts, heat sink, make-up plate, photocopier roller, and marine usage.

| Standard | GB, EN, ANSI, JIS |

| Alloy | 1000, 2000, 3000, 5000, 7000 , 8000 series |

| Thickness | 0.3~4.0 mm |

| Width | 800~1600 mm |

| Length | 1000~5000mm; Coil |

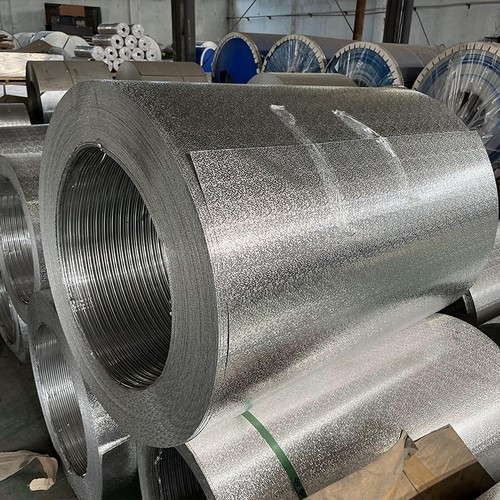

| Surface Treatment | Mill, bright, polished, hair line, brush, sand blast, checkered, embossed, etching, etc |

| Coating | Polyester (PE), Fluorocarbon (PVDF) |

| Temper | O, T3, T4, T6, T72, T81, T361, T351, T861, T3511, T8611, H111, H12, H14, H16, H18, H22, H24, H26, H28, H32, H34, H36, H38, etc |

| Coil weight | 3~20 tons |

| Packaging | Export standard packing or according to customers’ requirements. |

| Certificate | ISO9001:2008, SGS |

| Shipment | Within 10-15 workdays, 25-30 days when the quantity is beyond 1000 tons. |

| Elements | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others | Al | |||

| Content (max) | 0.60 | 0.70 | 0.30 | 1.0-1.5 | 0.2-0.6 | 0.10 | 0.25 | 0.10 | 0.15 | Remain | |||

| Material | Thickness (mm) | Tensile Strength (KIS) | Yield Strength (KIS) | Elongation (KIS) |

| 3005-O | 0.2 - 3.0 | 20 | 8 | 22 |

| 3005-H14 | 3.0 - 6.0 | 29 | 28 | 4 |

| 3005-H18 | 3.0 - 6.0 | 37 | 36 | 2 |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

Technology & Innovation

Team & Quality

Service & Support

| microchannel aluminum coils | 6061 aluminum coils for sale |

| ruud aluminum coils | 7075 aluminum coils for sale |

| 0.7ohm x-grid coils iron chromium aluminum a1 | aluminum alloy coils |

| 2017 aluminum or cooper coils for ac | aluminum coils abc supply |

| ace foam n clean aluminum coils | alcoa aluminum coils |

| acl aluminum coils oh | adp aluminum coils |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat