Related products

live a message

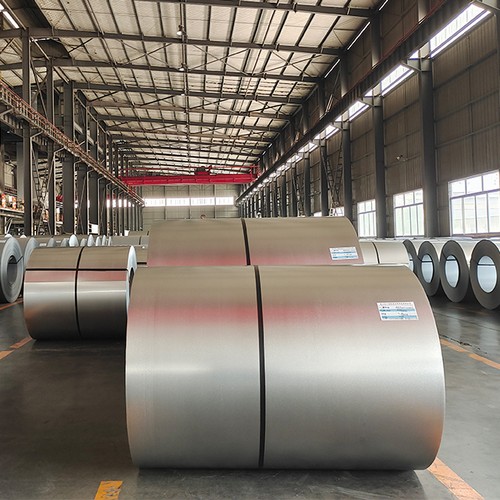

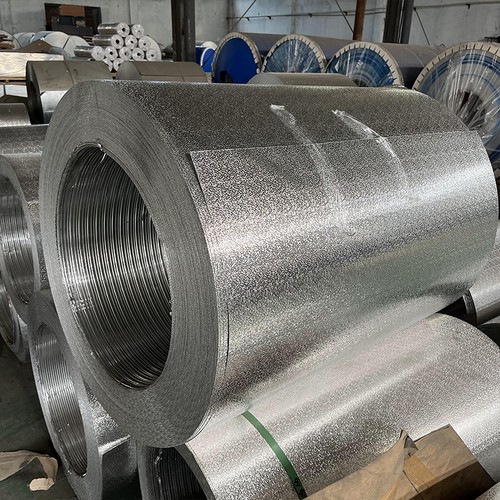

1060 aluminum coil contains more than 99.6% aluminum as a commonly used series. 1060 aluminum coils are widely used in aerospace, transportation and other industrial fields. At the same time, they are often subject to impact loads under high temperature and high pressure conditions in various other complex working environments.

Width | 20-3000mm or customized | Thickness | 0.1-120mm or customized |

Length | 100-12000mm or customized | Certificate | ISO, SGS, BV |

Standard | JIS, AISI, ASTM, GB, DIN, EN, etc. | ||

Brand | 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 5A05 etc. 6000 Series: 6061 6063 6082 6A02 etc. 7000 Series: 7050 7475 7075 etc. 8000 Series: 8A06 8011 8090 etc. | ||

Surface | Coating, Embossing, Drawing, Polishing, Anodizing, etc. | ||

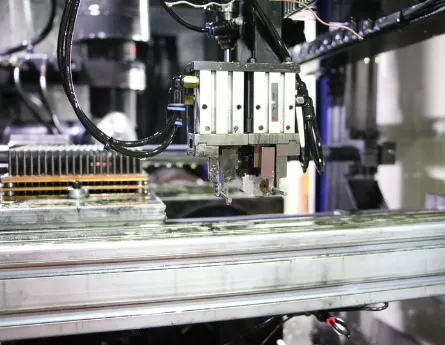

OEM Service | Punching, Cutting Special Size, Making Flat Surface, Surface Treatment, etc. | ||

Delivery Time | Received 30% after deposit 7-15 working days | ||

Application | Construction, Shipbuilding, Decoration, Industry, Manufacturing, Machinery, Hardware and other fields | ||

Sample | Free Offers Sample | ||

Packaging | Strapping, Plastic bag, Film, Wooden pallet standard seaworthy export packing or according to customer requirement | ||

Chemical Composition

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others: Each | Others: Total | Al: Min. |

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | 0.05 | 0.03 | 0.03 | - | 99.50 |

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | 0.05 | 0.03 | 0.03 | - | 99.60 |

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | 0.04 | 0.03 | 0.05 | - | 99.70 |

1100 | 0.95 Si Fee | 0.05~0.20 | 0.05 | - | - | 0.1 | - | 0.05 | 0.15 | 99.0 | |

2014 | 0.5~1.2 | 0.7 | 3.9~5.0 | 0.4~1.2 | 0.2~0.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | Allowance |

2017 | 0.2~0.8 | 0.7 | 3.5~4.5 | 0.4~1.0 | 0.4~0.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | 91.5 - 95.5 |

2024 | 0.50 | 0.50 | 3.8~4.9 | 0.3~0.9 | 1.2~1.8 | 0.10 | 0.25 | 0.15 | 0.05 | 0.15 | Allowance |

3003 | 0.60 | 0.70 | 0.05~0.20 | 1.0~1.5 | - | - | 0.10 | - | 0.05 | 0.15 | Allowance |

3A21 | 0.60 | 0.70 | 0.20 | 1.0-1.6 | 0.05 | - | 0.15 | 0.1-0.2 | - | - | Allowance |

3004 | 0.30 | 0.70 | 0.25 | 1.0~1.5 | 0.8~1.3 | - | 0.25 | - | 0.05 | 0.15 | Allowance |

3005 | 0.60 | 0.70 | 0.30 | 1.0~1.5 | 0.2~0.6 | 0.10 | 0.25 | 0.10 | 0.05 | 0.15 | Allowance |

3105 | 0.60 | 0.70 | 0.30 | 0.3~0.8 | 0.2~0.8 | 0.20 | 0.40 | 0.10 | 0.05 | 0.15 | Allowance |

5005 | 0.30 | 0.70 | 0.20 | 0.20 | 0.5~1.1 | 0.1 | 0.25 | - | 0.05 | 0.15 | Allowance |

5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2~2.8 | 0.15~0.35 | 0.10 | - | 0.05 | 0.15 | Allowance |

5754 | 0.40 | 0.40 | 0.10 | 0.50 | 2.6~3.6 | 0.30 | 0.20 | 0.15 | 0.05 | 0.15 | Allowance |

5A05 | 0.50 | 0.50 | 0.10 | 0.3-0.6 | 4.8-5.5 | - | 0.20 | - | 0.05 | 0.05 | Allowance |

5083 | 0.40 | 0.40 | 0.10 | 0.4~1.0 | 4.0~4.9 | 0.05~0.25 | 0.25 | 0.15 | 0.05 | 0.15 | Allowance |

6061 | 0.40~0.8 | 0.70 | 0.15~0.4 | 0.15 | 0.8~1.2 | 0.04~0.35 | 0.25 | 0.15 | 0.05 | 0.15 | Allowance |

6082 | 0.70~1.3 | 0.50 | 0.10 | 0.4~1.0 | 0.6~1.2 | 0.25 | 0.20 | 0.10 | 0.05 | 0.15 | Allowance |

7075 | 0.40 | 0.50 | 1.2~2.0 | 0.30 | 2.1~2.9 | 0.18~0.28 | 5.1~6.1 | 0.20 | 0.05 | 0.15 | Allowance |

Mechanical Properties

Tensile Strength (MPa) | Test Stress 0.2% (MPa) | Elongation Rate D10 (%) |

110-136 | ≥75 | 3-5 |

Physical Performance

Density | Melting Point | Modulus of Elasticity | Thermal Conductivity | Thermal Expansion | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2.7 Kg/m³ | 649 °C | 70-80 GPa | 234 W/m.K | 23.6× 10-6/K

Chemical Composition

Mechanical Properties

Physical Performance

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

Technology & Innovation

Team & Quality

Service & Support

| american standard aluminum coils | polished aluminum coils |

| coated aluminum coils | polished aluminum coils factories |

| coated aluminum coils factory | polished aluminum coils factory |

| coated aluminum coils manufacturers | polished aluminum coils manufacturer |

| coating aluminum coils | polished aluminum coils manufacturers |

| coating color aluminum coils factory | polished aluminum coils supplier |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat