Related products

live a message

Hot rolled steel involves melting primarily iron and sometimes steel as well as other elements at extreme temperatures and then rolling it into a long, flat strip that gets wound up into coil form.

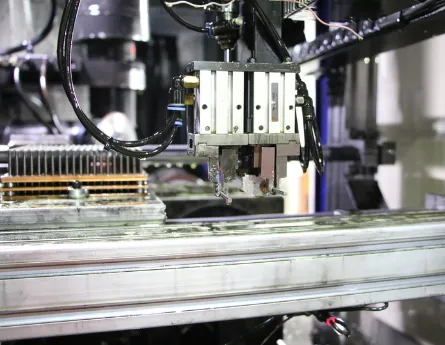

The first step in the hot rolling process is to heat the steel, element, or mineral mixture to intense heat above its recrystallization temperature. Once it is heated above this point, the steel becomes malleable. It is then fed into rolling machinery, where it can be shaped and easily formed. This hot-rolled carbon steel process allows for the ability to produce large quantities of steel in a single batch as minimal additional processing is required.

After the carbon steel is processed, it is then cooled to room temperature, which normalizes it. The heating and slow cooling process of steel alter the microstructure of the metal, which increases its ductility and strength. When forming steel, enhanced ductility is an important factor in obtaining its required shape. The exact mix of additional elements to the iron content determines the grade of the steel and its unique strength, forming, and hardness characteristics. Carbon and manganese are the two primary additional elements that influence the outcome of the particular grade of material, but other elements can play a key role as well.

Additionally, hot rolled steel shrinks slightly during the cooling phase, resulting in slight variations in the exact thickness and width of the coil. The finished product will not always meet the specific target that was originally intended. For this reason, there are industry-defined standard tolerances and ranges for flat-rolled steel products. Production of hot-rolled steel is both an art and science that truly requires a delicate balance. Oftentimes, additional and readily available processing is necessary for areas where tight tolerances are essential.

Product Name | Cold Rolled/ Hot Rolled Carbon Steel Coils Price |

Standard | AISI,ASTM,DIN,JIS,GB,JIS,SUS,EN,etc. |

Material | Q195, Q215,Q235,Q345,ST37, A36,45# ,16Mn, SPHC,SGCC,CGCC |

Thickness(mm) | Hot Rolled Thickness:2.75mm-100mmCold Rolled Thickness:0.2mm-3mm As Your Request |

Width(mm) | 45mm-2200mm, As Your Request |

Technique | Hot rolled / cold rolled |

Surface | Bare,Black,Oiled,Shot Blasted,Spray Paint,Coated,Galvanized,or as Your Request |

Coil ID | 508-610mm or as per your request |

Coil Weight | 3~5 Tons or as per your request |

Application | Construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

Packing | Standard Export packing |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

Technology & Innovation

Team & Quality

Service & Support

| carbon steel coils factories | carbon steel coil nails manufacturers |

| carbon steel coils | carbon steel coil nails factory |

| carbon steel coil/plate factories | carbon steel coil nails factories |

| carbon steel coil/plate | carbon steel coil nails |

| carbon steel coil wholesaler | carbon steel coil manufacturers in china |

| carbon steel coil supplier | carbon steel coil manufacturers |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat