Related products

live a message

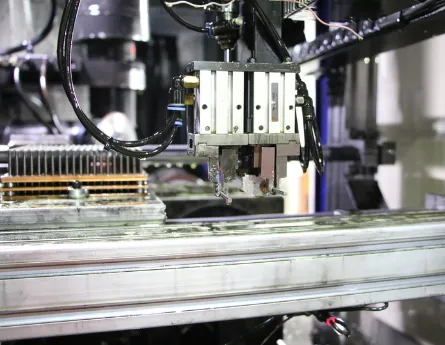

Carbon steel coil is a roll product made of carbon steel material, which is widely used in many industries such as construction, automobile manufacturing, mechanical processing, home appliances, ships, oil and gas, etc. Similar to carbon steel plates, carbon steel coils have good strength, toughness and processability, but are provided in roll form for easy large-scale production and transportation.

Material and alloy classification

The material of carbon steel coils is usually composed of iron and carbon alloys. According to the carbon content, carbon steel can be divided into the following categories:

Low carbon steel (mild steel): The carbon content is usually less than 0.3%, with good ductility, weldability and processability, and is often used in construction, home appliances and other fields.

Medium carbon steel: The carbon content is usually between 0.3% and 0.6%, with good strength and plasticity, and is widely used in machinery, automotive parts and structural parts.

High carbon steel: The carbon content is usually higher than 0.6%, with higher hardness and wear resistance, and is often used to manufacture tools, springs and knives, etc.

Specifications of carbon steel coils

The specifications of carbon steel coils usually include thickness, width, inner diameter and outer diameter. Common specifications are:

Thickness: The thickness of carbon steel coils usually ranges from 0.2mm to 6mm, which can be customized according to customer needs.

Width: Common widths are 600mm, 1000mm, 1250mm, 1500mm, etc. Different widths are suitable for different industrial needs.

Inner diameter: The inner diameter of carbon steel coils is usually 508mm or 610mm, which is suitable for the storage and transportation of coils.

Outer diameter: The outer diameter of carbon steel coils generally ranges from 600mm to 1500mm, which varies according to the thickness and specifications of the coils.

Application areas of carbon steel coils

Carbon steel coils are widely used in many industries due to their excellent processability and low production costs:

Construction industry: used to manufacture steel structures, steel beams, steel columns, roofs, etc., especially for large-scale construction projects.

Automotive industry: used to manufacture car bodies, chassis, doors, auto parts, etc. Carbon steel coils have good ductility and can be deep stamped.

Home appliance industry: used to manufacture the outer shell and internal parts of home appliances such as refrigerators, washing machines, air conditioners, etc., because they are easy to process and have low costs.

Machinery manufacturing: Carbon steel coils are widely used in the manufacture of mechanical parts, equipment housings, tool racks, etc.

Oil and gas industry: used to manufacture pressure vessels, storage tanks, pipelines and other equipment, low carbon steel coils are often used for conveying pipelines and other load-bearing structures.

Shipbuilding: Carbon steel coils are widely used in the manufacture of hull structures and ship parts.

Transportation: used to produce railway carriages, vehicle chassis, shelves, etc., especially in applications requiring strong load-bearing capacity, carbon steel coils perform very well.

| Product Name | carbon steel coil |

| Wall Thickness | 0.17mm-1.7mm |

| Width | 600mm-1250mm |

| Tolerance | Thickness:±0.03mm, Width: ±50mm, Length: ±50mm |

| Material | Q345B,Q345C,Q345D,Q345E,Q390,Q390B,Q390C, |

| Q390D,Q390E,Q420,Q420B,Q420C,Q420DQ420E, | |

| Q460,Q460D,Q500C,Q500D,Q500E,Q550C,Q550D, | |

| Q550E,Q620C,Q620D,Q620E,Q690A,Q690B,Q690C, | |

| Q690D,Q690E,Q690D,Q690C,Q890C,Q890D | |

| 16Mo3,16MnL,16MnR ,16Mng,16MnDR | |

| Technique | Hot/cold Rolled |

| Surface treatment | Top paint: PVDF, HDP, SMP, PE, PU |

| Prime paint: polyurethane, epoxy, PE | |

| Back paint: epoxy, modified polyester | |

| Standard | ASTM, JIS, EN |

| Certificate | ISO, CE |

| Payment terms | 30% T/T deposit in advance, 70% T/T balance within 5 days after B/L copy, 100% Irrevocable L/C at sight, 100% Irrevocable L/C after receive B/L 30-120 days, O/A |

| Delivery times | Delivered within 30 days after the receipt of deposit |

| Package | tied up with steel strips and wrapped with water proof paper |

| Loading port | Qingdao, China |

| Application | Widely used in roofing sheet, window-shades, car ceiling, the shell of the car, air conditioner, outer shell of water machine, steel structure etc |

| Advantages | 1. Reasonable price with excellent quality |

| 2. Abundant stock and prompt delivery | |

| 3. Rich supply and export experience, sincere service |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

Technology & Innovation

Team & Quality

Service & Support

| cold rolled carbon steel coil | cold rolled carbon steel coil factories |

| wholesale carbon steel coil | cold reduced carbon steel coil |

| standard sizes carbon steel coil quotes | coiled spring pin 7 16 high carbon steel |

| spcc carbon steel coil | coiled spring pin 3 8 x 2 high carbon steel |

| mild carbon steel coil | coiled spring pin 3 8 high carbon steel |

| mild carbon black steel coil quotes | coiled spring pin 1mm x 2 high carbon steel |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat