Related products

live a message

Alloy Steel 4340, also referred to as AISI 4340, is a nickel, chromium, and molybdenum alloy steel. This heat-treatable alloy is known for its toughness and high strength in a heat-treated condition. It is weldable by both fusion and resistance welding and offers good ductility in the annealed condition.

Steel 4340 is a medium-carbon nickel-chromium-molybdenum steel alloy with excellent tensile strength, toughness, and fatigue resistance. Since the material usually comes in the annealed condition, additional heat treatments (oil quenching and tempering, or normalizing and tempering) can produce parts with even higher strength and fatigue resistance.

Furthermore, Steel 4340 is a wear-resistant material with especially good abrasion resistance, shock- and -impact resistance, and excellent atmospheric corrosion resistance. The alloy also possesses very good ductility, especially in the annealed condition, where it can be easily formed and machined.

Thanks primarily to its toughness, Steel 4340 finds use in heavy machinery, specifically for the manufacturing of transmission parts, such as heavy-duty shafts, gears, and axles.

| Property | Imperial | Metric |

| Mean Coefficient of Thermal Expansion 68 °F to 212 °F (20 °C to 100 °C) oil-hardened; tempered @ 1100 °F (600 °C) | 6.83 [10-6/°F] | 12.3 [10-6/K] |

| Mean Coefficient of Thermal Expansion 68 °F to 390 °F (20 °C to 200 °C) oil-hardened; tempered @ 1100 (600 °C) | 7.06 [in/in/°F·106] | 12.7 [10-6/K] |

| Mean Coefficient of Thermal Expansion 72 °F to 500 °F (22 °C to 260 °C) normalized & tempered | 7.0 [10-6/°F] | 12.6 [10-6/K] |

| Mean Coefficient of Thermal Expansion 68 °F to 750 °F (20 °C to 400 °C) oil hardened; tempered @ 1100 (600 °C) | 7.61 [10-6/°F] | 13.7 [10-6/K] |

| Thermal Conductivity (@ 212 °F) (@ 100 °C) | 309 Btu/(hr/ft²/in/°F) | 44.5 [W/m-K] |

| Property | Imperial | Metric |

| Ultimate Tensile Strength | 161000 psi | 1100 MPa |

| Yield Strength | 103000 psi | 710 MPa |

| Elongation at Break (in 4D) | 13.2 % | 13.2 % |

| Rockwell Hardness C | 35 | 35 |

| Rockwell Hardness B | 99 | 99 |

| Brinell Hardness | 321 | 321 |

| Knoop Hardness | 348 | 348 |

| Vickers Hardness | 339 | 339 |

| Reduction of Area | 36 % | 36 % |

| Machinability (annealed and cold-drawn condition) | 50 % | 50 % |

| Modulus of Elasticity | 29700 ksi | 205 |

| Shear Modulus | 11600 ksi | 80 GPa |

| Poisson’s Ratio | 0.29 | 0.29 |

| Bulk Modulus | 20300 ksi | 140 GPa |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

Technology & Innovation

Team & Quality

Service & Support

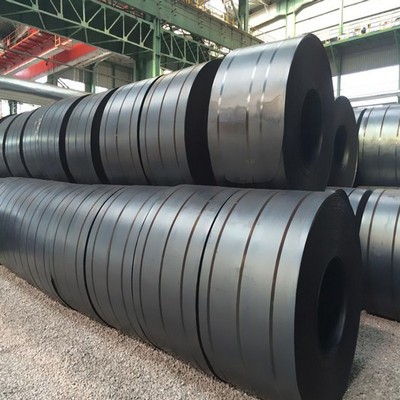

| coiled spring pin 13 32 x 2 high carbon steel | carbon steel coil/plate factories |

| coiled carbon steel tubing | carbon steel coil/plate |

| china carbon steel coil | carbon steel coil wholesaler |

| cheap cold rolled carbon steel coil | carbon steel coil supplier |

| carbon steel wire coils | carbon steel coil strip in stock |

| carbon steel tubing coil | carbon steel coil strip |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat