Related products

live a message

DC01, DC02, DC03, DC04, DC05, DC06 are steel grades of European standard DIN EN 10130, 10209 and DIN 1623, which are specified cold rolled steel. The grades are classified according to the maximum permissible yield strength.

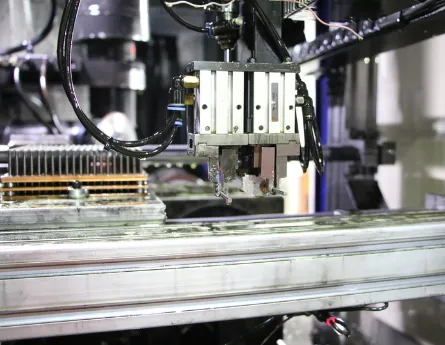

DC steel coils have high tensile strength and elongation, giving them good processing properties during the manufacturing process. This makes DC steel coil widely used in the manufacturing of automotive parts, home appliances, construction and other parts that require high strength and precision. DC steel coil has excellent weldability and machinability with its low carbon content. So it can be processed through various welding and cutting processes, such as arc welding, gas shielded welding, laser cutting, etc., to meet the needs of material processing performance in different fields. Lastly, it meets the requirements of environmental protection and sustainable development by releasing low carbon emission.

Product Name | DC01/DC02/DC03/DC04 Cold Rolled Steel Coil |

Production Process | Hot Rolling, Cold Rolling |

Material Standards | AISI, ASTM, ASME, DIN, BS, EN, ISO, JIS, GOST, SAE, etc. |

Width | 45mm-2200mm |

Length | Custom Size |

Thickness | Hot Rolling: 2.75mm-100mm |

Delivery Conditions | Rolling, Annealing, Quenching, Tempered or Standard |

Surface Process | Ordinary, Wire Drawing, Laminated Film |

Chemical Composition

C: max. 0,08 %

Mn: max. 0,40 %

P: max. 0,03 %

S: max. 0,03 %

Mechanical Properties

Steel Grade | Yield Strength (MPa) min | Tensile Strength (MPa) min | Elongation % min | Old Description |

DC01 | ≤ 280 | 270-410 | 28 | St 12-03 |

DC03 | ≤ 240 | 270-370 | 34 | St 13-03 |

DC04 | ≤ 210 | 270-350 | 38 | St 14-03 |

DC05 | ≤ 180 | 270-330 | 40 | St 15-03 |

DC06 | ≤ 170 | 270-330 | 41 | - |

DC07 | ≤ 150 | 250-310 | 44 | - |

Scope of Application

DC01 can be used for simple forming work, for example Bending, embossing, beading and pulling.

DC03 is suitable for forming requirements like Deep drawing and difficult profiles suitable.

DC04 is suitable for high deformation requirements.

DC05 is a thermal forming grade, it is suitable for higher forming requirements.

DC06 is a grade for special deep drawing, suitable for the higher deformation requirements.

DC07, this superior deep drawing quality is suitable for highest deformation requirements.

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

Technology & Innovation

Team & Quality

Service & Support

| alloy carbon steel coil | carbon steel coils quotes |

| hot rolled carbon steel coil manufacturer | carbon steel coils factory |

| custom low carbon steel coil | carbon steel coils factories |

| custom hot rolled carbon steel coil | carbon steel coils |

| custom carbon steel coil | carbon steel coil/plate factories |

| low carbon steel coil | carbon steel coil/plate |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat