Related products

live a message

Stainless steel 410 is a basic martensitic grade which contains 11.5% chromium, offering both exceptional wear and corrosion resistance. SS 410 is corrosion resistant to some chemicals, food, mild acids, water, and air. It also proves adequate resistance to nitric acid, concentrated sulfuric acid, dilute acetic acid and naphtha. Elevated mechanical properties and corrosion resistance are achieved with stainless steel 410 when it's hardened and tempered.

| Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316Ti, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L |

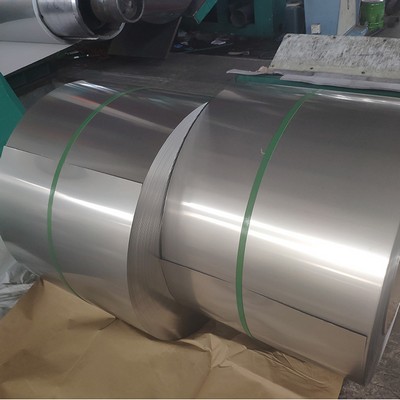

| Thickness | 0.02mm – 5.0mm |

| Width | 3.2mm – 1500mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | STAINLESS STEEL SOFT, DEEP DRAW, EXTRA DEEP DRAW, QUARTER HARD, HALF HARD, FULL HARD. |

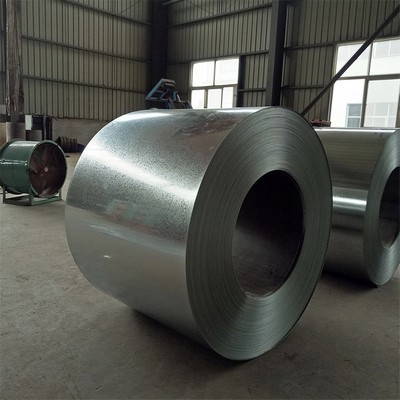

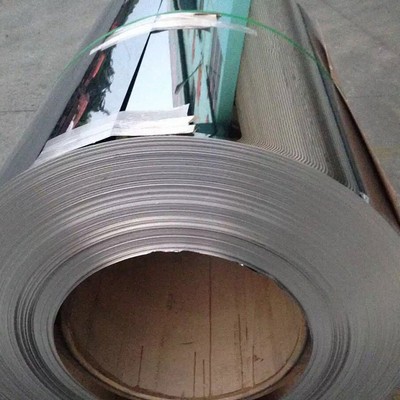

| Form | Coil / Strip |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Make | JINDAL, BAHRU, POSCO KOREA, POSCO THAINOX, COLUMBUS, ACERINOX, APERAM, TISCO, NISSHIN, NIPPON AND MANY MORE MILLS. |

Grade | C | Mn | Si | P | S | Cr | Ni | |

410 | min. max. | – 0.15 | – 1 | – 1 | – 0.04 | – 0.03 | 11.5 13.5 | 0.75 |

Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion | Thermal Conductivity | Specific Heat 0-100°C | Electrical Resistivity (nΩ.m) | |||

0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

410 | 7800 | 200 | 9.9 | 11 | 11.5 | 24.9 | 28.7 | 460 | 570 |

Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

BS | En | No | Name | ||||

410 | S41000 | 410S21 | 56A | 1.4006 | X12Cr13 | 2302 | SUS 410 |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

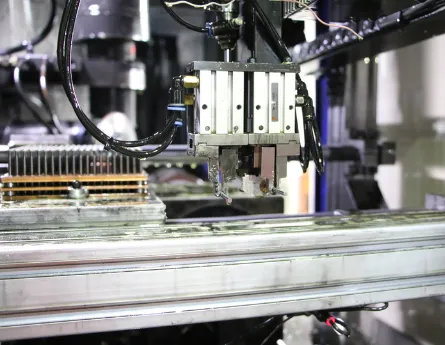

Technology & Innovation

Team & Quality

Service & Support

| 8k stainless steel coil | stainless steel electric coil range |

| ba stainless steel coil | stainless steel electric coil stove |

| best stainless steel coil build | stainless steel electric range with coil elements |

| china 201 stainless steel coil | stainless steel electric range with coils |

| china 301 stainless steel coils manufacturer | stainless steel electric stove with coil burners |

| china 304l stainless steel coil supplier | stainless steel feeler coils |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat