Related products

live a message

Type 410 is a corrosion and heat resistant martensitic stainless steel containing approximately 12% chromium offering a wide range of mechanical properties through heat treatment. This grade offers a moderate level of corrosion resistance and the maximum resistance is obtained by hardening through heat treatment followed by polishing. Type 410 is used for cutlery applications, kitchen utensils and hand tools and is magnetic in both the annealed and hardened conditions.

Type 410 stainless steel displays high strength, heat resistance, and good ductility, making it ideal for the manufacturing of products like bolts, nuts, springs and fasteners, as it can be machined after tempering or annealing. This grade is also commonly used in manufacturing of durable cutlery and kitchen utensils, where its properties allow it to resist the acidity of food products and general corrosion.

While 410 stainless steel materials can readily be welded, it is limited by its hardenability, and it should be pre-heated to reduce the risk of cracking. Post weld heat treatment is not necessarily needed, but recommended to retain required properties, and should be air cooled after annealing.

| Grades | Stainless Steel J1, J2, J4, 201, 202, 301, 304, 304H, 304L, 309, 309S, 310, 310S, 316, 316L, 316Ti, 321, 321H, 347, 409, 410, 410S, 420, 430, 441, 904L |

| Thickness | 0.02mm – 5.0mm |

| Width | 3.2mm – 1500mm |

| Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, AS PER CUSTOMER’S REQUIREMENT |

| Type of Material | STAINLESS STEEL SOFT, DEEP DRAW, EXTRA DEEP DRAW, QUARTER HARD, HALF HARD, FULL HARD. |

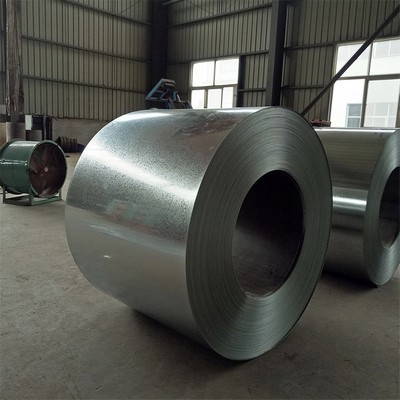

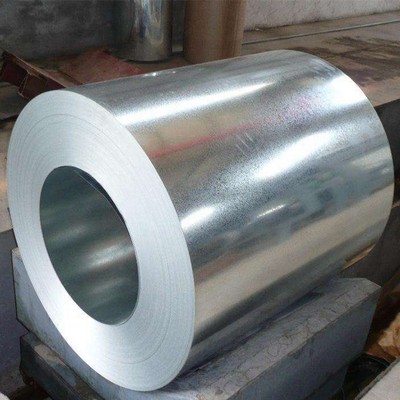

| Form | Coil / Strip |

| Test Certificate | Yes. |

| Finish | NO.1, 2B, 2D, 2H, 2R, No.4, HAIRLINE, SCOTCH BRITE, SATIN FINISH, NO.8, BA. |

| Make | JINDAL, BAHRU, POSCO KOREA, POSCO THAINOX, COLUMBUS, ACERINOX, APERAM, TISCO, NISSHIN, NIPPON AND MANY MORE MILLS. |

Grade | C | Mn | Si | P | S | Cr | Ni | |

410 | min. max. | – 0.15 | – 1 | – 1 | – 0.04 | – 0.03 | 11.5 13.5 | 0.75 |

Grade | Density (kg/m3) | Elastic Modulus (GPa) | Mean Coefficient of Thermal Expansion | Thermal Conductivity | Specific Heat 0-100°C | Electrical Resistivity (nΩ.m) | |||

0-100°C | 0-315°C | 0-538°C | at 100°C | at 500°C | |||||

410 | 7800 | 200 | 9.9 | 11 | 11.5 | 24.9 | 28.7 | 460 | 570 |

Grade | UNS No | Old British | Euronorm | Swedish SS | Japanese JIS | ||

BS | En | No | Name | ||||

410 | S41000 | 410S21 | 56A | 1.4006 | X12Cr13 | 2302 | SUS 410 |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

Technology & Innovation

Team & Quality

Service & Support

| china stainless steel coil | are stainless steel coils safe |

| coil of stainless steel | bending stainless steel tubing into coil |

| coil range stainless steel | bostitch stainless steel coil nails |

| coiled stainless steel tubing | can you use stainless steel coils in wattage mode |

| cold rolled stainless steel coil | coiled spring pins stainless steel |

| cold rolled stainless steel sheet in coil | dry burn stainless steel coil |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat