Related products

live a message

321 stainless steel is an austenitic stainless steel of excellent corrosion resistance at room temperature, as well as good high-temperature strength and creep resistance.

321 stainless steel has better crack resistance during the welding process owing to the titanium content. Besides, 321 stainless steel also has good processing and welding properties, which makes it easy to perform cutting, bending, welding and other processing operations. Its mechanical properties such as tensile strength, flexural strength and elongation are also outstanding, and can fulfill the requirements of use in various complex environments. Because 321 stainless steel coils have excellent corrosion resistance and high temperature performance, they are often used in petroleum, chemical industry, aviation, aerospace fields. In the petroleum and chemical industries, since the production process involves a large amount of corrosive media such as acids, alkalis, and salts, 321 stainless steel coil manages to resist the corrosion of these media and ensure the long-term stable operation of the equipment.

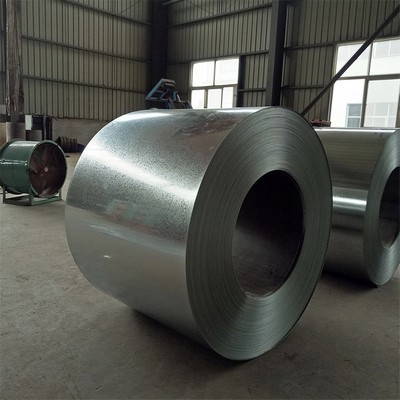

Product Name | 321 Stainless Steel Coil |

Type | Steel Coil |

Thickness | 2.5mm-10.0mm |

Length | 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc. |

Width | 610mm-2000mm |

Standard | ASTM, AISI, JIS, GB, DIN, EN, etc. |

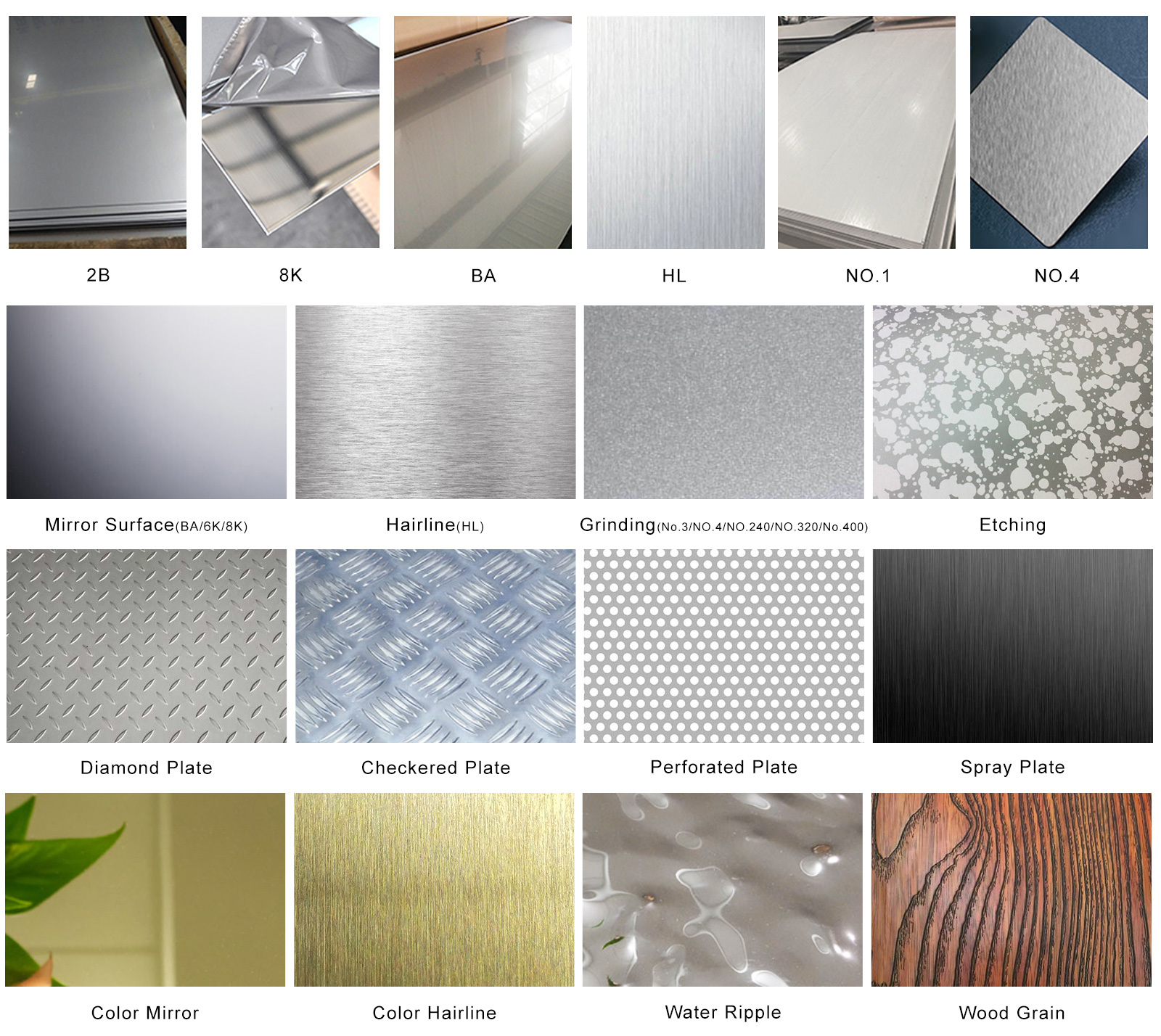

Surface | BA, 2B, NO.1, NO.4, 4K, HL, 8K, etc. |

Scope of Application | Widely used in high temperature and electrical industry, medical equipment construction, chemical, food industry, agriculture and ship parts, food and beverage packaging, Kitchen supplies, trains, airplanes, conveyor belts, vehicles, bolts, nuts, springs and screens, etc. |

Certificate | ISO, SGS, BV, etc. |

Production Technology | Hot Rolling, Cold Rolling |

Edge Processing | Edging, Trimming |

Chemical Composition

C | Si | Mn | Cr | Ni | S | P |

≤ 0.08 | ≤ 0.75 | ≤ 2.0 | 17.0~19.0 | 9.0~12.0 | ≤ 0.03 | ≤ 0.045 |

Mechanical Properties

Tensile Strength Kb (MPa) | Yield Strength σ0.2 (MPa) | Elongation D5 (%) | Hardness |

≥520 | ≥205 | ≥ 40 | ≤ 187HB;≤ 90HRB;≤ 200HV |

Physical Performance

Density(g/cm³) | Modulus of Elasticity(Gpa) | Coefficient of Thermal Expansion(10-6/°C) | Coefficient of Thermal Conductivity(W/m*K) | Resistivity(ΜΩ. cm) |

7.92 | 193 | 16.6 | 16.0 | 72 |

Surface Selection

| Surface | Characteristic | Summary of Manufacturing Method |

| NO.1 | Silvery white | Hot rolled to specified thickness |

| NO.2D | Silvery white | After cold rolling, heat treatment and pickling are carried out |

| NO.2B | Gloss is stronger than No.2D | After No.2D treatment, the final light cold rolling is carried out through the polishing roller |

| BA | As bright as a sixpence | No standard, but usually a bright annealed surface with high reflectivity. |

| NO.4 | Intermediate grinding | Polished surface obtained by grinding with 150~180# strop abrasive tape |

| HL | Hairline grinding | Suitable particle material for hair stripe grinding (150~240#) with many grains |

| NO.8 | Mirror ultrafinish | The mirror is ground with a polishing wheel |

We are happy to answer any questions you have regarding our product lines and services. Please tell us a little more about yourself and we will have someone contact you as soon as possible.

Speak to a Steel Expert

Behind the growth and success of Kuaima Steel is years of hard work and dedication in the steel industry and meeting customers' needs on time. Advanced technology, standard products, certified quality standards and the bestcustomer service make Kuiama Steel a true leader in the global market.

Quality & experience

Technology & Innovation

Team & Quality

Service & Support

| 1 16 stainless steel coil | 1/4 stainless steel tubing coil |

| 1 3 4 stainless steel ss siding nail coil lowes | 1/8 stainless steel tubing coil |

| 1 inch stainless steel coil | 3/4 stainless steel coil tubing |

| 1 stainless steel coil | 3/4 stainless steel tubing coil |

| 1.4307 stainless steel coil | 409 baosteel aisi 201 stainless steel coil |

| 1.4462 stainless steel coil | best temp for stainless steel coils |

Every industry has its unique set of material specifications and needs. That’s why you can count on the exceptional experience and industry knowledge of the professionals at Kuaima Steel - Meeting the Exact Needs of Every Industry That Uses steel.

WeChat

WeChat